Single Seal Pneumatic Diaphragm Pump Manufacturer – GLFZ Axial Flow Evaporating Circulating Pump – State Machinery Equipment Manufacturing

Single Seal Pneumatic Diaphragm Pump Manufacturer – GLFZ Axial Flow Evaporating Circulating Pump – State Machinery Equipment Manufacturing Detail:

Product Features

The horizontal axial flow pump works by using the horizontal thrust along the pump axis direction generated by the rotation of the impeller, so it is also called the horizontal axial flow pump. Mainly used in the evaporation of diaphragm method caustic soda, phosphoric acid, vacuum salt production, lactic acid, calcium lactate, alumina, titanium dioxide, calcium chloride, ammonium chloride, sodium chlorate, sugar, molten salt, paper, waste water and other industries. Concentration and cooling are used to increase the production capacity of the equipment and increase the heat transfer coefficient of the heat exchanger for forced circulation. Therefore, it can also be called an axial flow evaporative circulation pump.

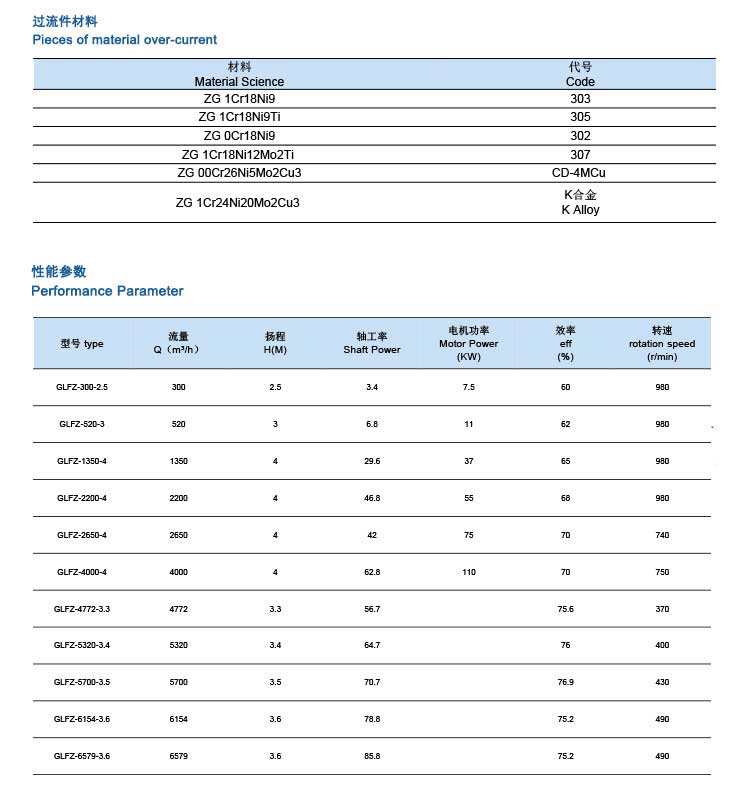

1. The speed is low, the general speed is within 980r/min, which meets the requirements of the crystallization process and runs smoothly

2. Excellent hydraulic performance, efficiency ≥70% high efficiency area, good anti-cavitation performance

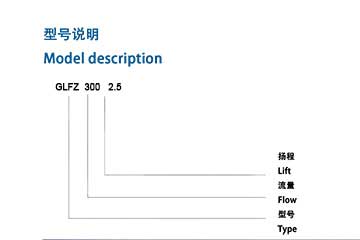

3. Consider that the flow direction of the pump medium is vertically downward and horizontally out. Due to the great influence of the water flow force on the pump shaft, a pump shaft jacket protection device is added in the pump body. The subduction force of the medium is transferred to the pump body, thereby ensuring the stable operation of the pump, greatly reducing the influence of the medium on the force of the mechanical seal, and prolonging the service life of the machine seal. The improvement of this structure has taken a big step in the domestic similar products. In addition, the pump body adopts integral casting with good rigidity, and the intermediate support structure is connected and stable. The horizontal axial flow pump has no guide vanes.

4. The direct connection type has small installation size, low noise, low failure rate and high efficiency.

Type Designation

Performance Parameter

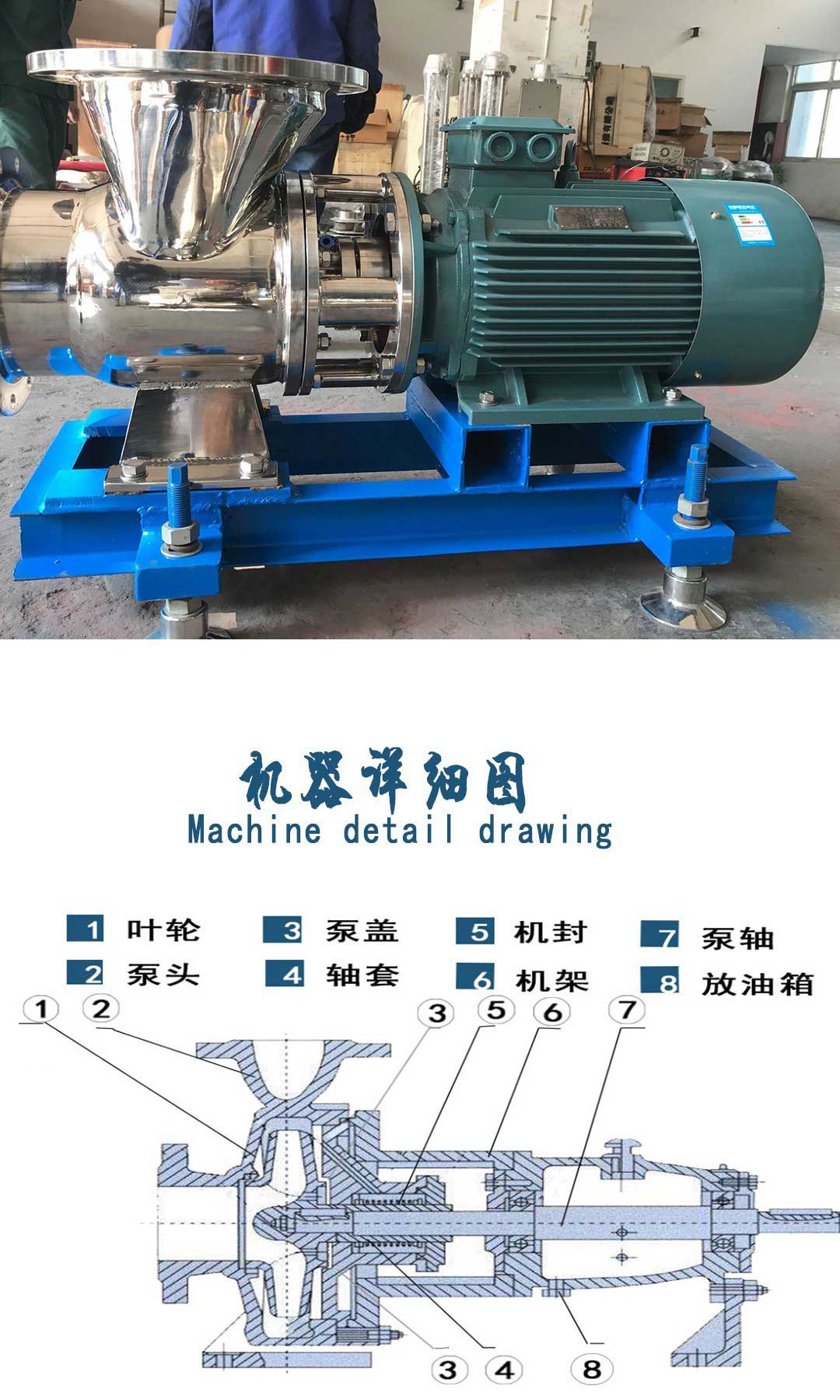

Product detail pictures:

Related Product Guide:

We strive for excellence, services the customers", hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for Single Seal Pneumatic Diaphragm Pump Manufacturer – GLFZ Axial Flow Evaporating Circulating Pump – State Machinery Equipment Manufacturing , The product will supply to all over the world, such as: Detroit, Nepal, Wellington, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.